SERVICE & TROUBLESHOOTING GUIDE

If your looking to get to the next level in your refrigeration career and get the pay rate you deserve, start taking some action, study this guide and take your career to new heights.

Clicking the "Yes, I want This Button" will automatically get you this guide for FREE

Introducing...

6 COMMON COMPRESSOR ISSUES

Ready to Build Your Confidence When Working with Compressors?

- Understand Overheating

- Prevent Flooded Starts

- Avoid Liquid Slugging

- Prevent Liquid Floodback

- Maintain Oil Levels

- Eliminate Contamination

It’s time to level up your skills and troubleshoot with confidence!

Overheating

Compressor overheating is a common issue that can significantly impact system performance. This guide shows you the warning signs, causes, and corrective actions to keep your compressor running at optimal temperatures..

Flooded Starts

A flooded start can cause premature wear and tear. Discover the telltale signs of a flooded start, why it happens, and how to prevent it for a smoother startup and extended equipment life..

Liquid Slugging

Liquid slugging is one of the most damaging issues a compressor can face. This module walks you through what liquid slugging looks like, why it occurs, and the steps to take to avoid this costly problem.

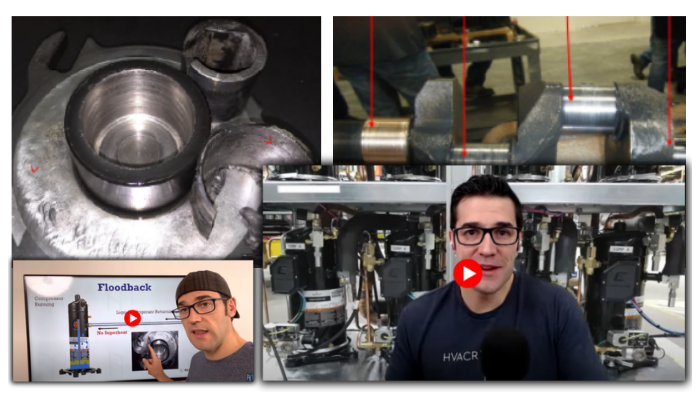

Liquid Floodback

Liquid floodback can cause internal damage and reduce compressor efficiency. Learn how to identify floodback conditions, understand their causes, and explore effective solutions to protect your compressor.

System Oil Loss

Without proper oil levels, compressor parts can wear down quickly. This section dives into why oil loss happens, how it affects your system, and the steps you can take to ensure consistent oil levels for long-term durability.

Contamination

Contaminants in the system can lead to compressor damage and operational issues. Find out what causes contamination, how to recognize it, and the cleaning and prevention methods to keep your system running smoothly.

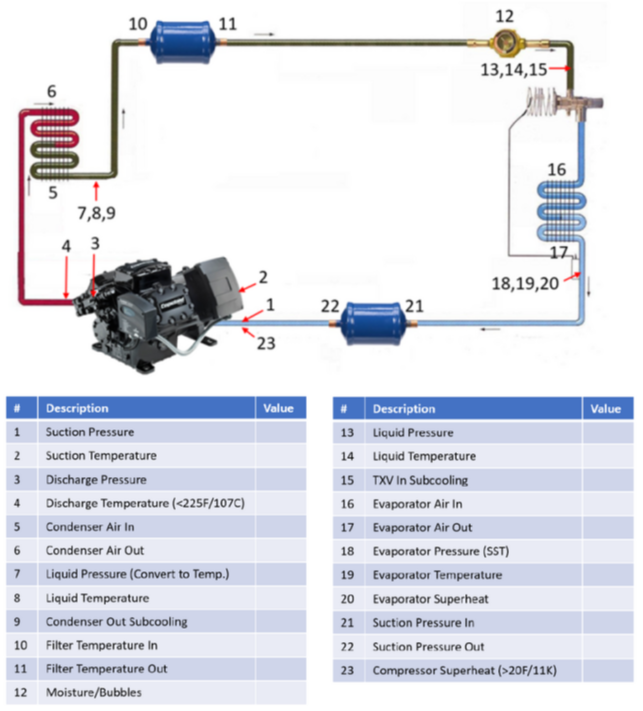

SYSTEM CHECK POINTS

Inside the guide, you will have access to the essential system checkpoints you need to perform for an efficient service call. By following these checkpoints, you’ll be equipped to evaluate system health accurately, identify potential problems before they escalate, and ensure optimal operation for your refrigeration systems.

Think of these checkpoints as the "vital signs" of the systems we work with. Just like a doctor checks your pulse and temperature, we measure pressures, temperatures, and inspect electrical components to understand how our systems are performing. These measurements provide crucial clues that guide us in diagnosing issues and ensuring everything runs smoothly.

Get ready to enhance your diagnostic skills and improve your service efficiency!

Yes, I want this Guide!

FEQUENTLY ASKED QUESTIONS

What is the purpose of the guide?

Is there any cost associated with the guide?

How do I download the guide?

Are the troubleshooting steps easy to follow?

If your looking to get to the next level in your refrigeration career and get the pay rate you deserve, start taking some action, study this guide and take your career to new heights.

Clicking the "Yes, I want This Button" will automatically get you this guide for FREE